Microtopping technique

The knowledge and craft you can count on at Texture Painting!

Creating an interior with Microtopping requires real craftsmanship. Texture Painting has developed its own techniques over the past 10 years and received the "Handmade in Belgium" label.

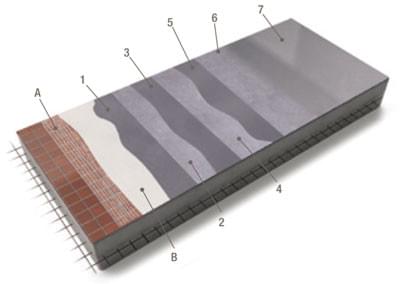

Microtopping is made up of cement and polymers. (Whereas with other decorative plasters, the main component is often lime and acrylic).

A Microtopping floor cannot be applied all at once. It is applied layer by layer, sanded each time, and finally a top coat is applied that fills all the pores.

Surface preparation

- The concrete floor or ceramic tiles are roughly sanded or leveled.

- Depending on the type and conditions of the substrate, a coating or moisture barrier will be applied in one or more layers.

Application Micro-topping system

- Applying the microtopping base coating

- Sanding and dust removal by vacuuming

- Applying the microtopping 1st finish coat

- Sanding and dust removal by vacuuming

- Applying the microtopping 2nd finish coat

- Sanding and dust removal by vacuuming

- Protective sealer. The type of sealer is chosen depending on the amount of traffic and the environment.

The result

The end result is very even, without sacrificing character. In addition to very tight results, Microtopping can be further personalized into artistic designs and special effects created by acidification and various application techniques.

Its adhesion quality makes it applicable to a variety of substrates, both horizontal and vertical. Microtopping has very high wear resistance, is easy to maintain, and ideal for use with underfloor heating. In addition, with its 2 to 4 mm thickness, Microtopping is also extremely suitable for applying over existing surfaces in renovations.